Products

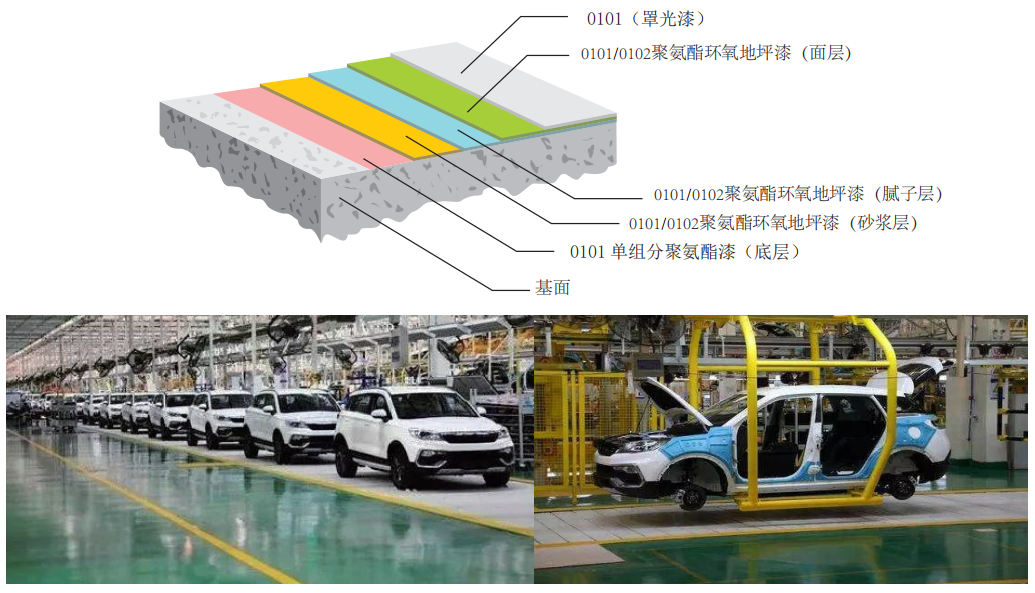

Polyurethane epoxy floor paint system

Product Details

Product features

-

Strong adhesion and good flexibility;

-

The coating is dense, the surface is smooth and it is extremely easy to clean.

-

The coating is wear-resistant, impact-resistant, pressure-resistant and has a long service life.

-

Oil-resistant, water-resistant and various organic and inorganic chemical media;

-

Good insulating properties;

-

The construction is fast and the cost is low

Scope of application

Applicable to the concrete surfaces inside various buildings

Electrical, electronic and mechanical manufacturing factories, workshops, warehouses

Food, medicine, chemical industry, tobacco, textile, clothing

Furniture, light industry, plastics, manufacturing of cultural and sports goods, parking lots

Hypermarkets, etc.

| Technical Specifications | |||

| Performance | Item | Technical Index (GB/T22374-2018) | Test Result |

| Drying Time | Tack-free time, h | ≤ 8 | Compliant |

| Hard dry time, h | ≤ 48 | Compliant | |

| Hardness | Pencil hardness (scratch) | To be agreed | 3H |

| Abrasion Resistance | 750g/500r | ≤ 0.030 | 0.022 |

| Impact Resistance | Heavy load | 1000g steel ball, 100cm height; no cracks/peeling of coating | Compliant |

| Skid Resistance | Dry friction coefficient | ≥ 0.50 | 0.55 |

| Water Resistance | 168h | No blistering/peeling; slight discoloration allowed | Compliant |

| Chemical Resistance | Oil resistance (120# solvent gasoline, 72h) | Same as above | Compliant |

| Alkali resistance (20%NaOH, 72h) | Same as above | Compliant | |

| Acid resistance (10%H₂SO₄, 48h) | Same as above | ||

| Matching Instructions | |||||

| Coating Layer | Material Model | Packaging Specification | Mix Ratio | Single Coat Consumption (kg/㎡) | Single Coat Thickness (mm) |

| Primer Coat | OVG-0101 Single-component Polyurethane Paint | 15KG | Single-component | 0.1-0.15 | 0.05-0.08 |

| Mortar Layer | OVG-0101/OVG-0102 Polyurethane Epoxy Floor Paint | 15KG/20KG | 3:04 | 0.3 | 0.25-0.30 |

| Putty Layer | OVG-0101/OVG-0102 Polyurethane Epoxy Floor Paint | 15KG/20KG | 3:04 | 0.1 | 0.07-0.08 |

| Topcoat 1 | OVG-0101/OVG-0102 Polyurethane Epoxy Floor Paint | 15KG/20KG | 3:04 | 0.15 | 0.08 |

| Finish Coat | OVG-0101 Single-component Polyurethane Paint | 15KG | Single-com | ||

Notes

-

The construction environment temperature should be 0-35℃, and the relative humidity should be 20%-80%.

-

When the temperature is too low, the drying process slows down; when it is too high, it causes difficulties in construction.

-

If the humidity is too low, it may cause incomplete drying, poor adhesion and other defects. If the humidity is too high, it is easy to have bubbles and heat rash.

-

For severely sandy and dusty floors, the amount of primer used will increase. It is recommended to use the primer to fully penetrate and reinforce until the overall color of the concrete is uniform without whitening, which can prevent the floor from peeling and hollowing.

-

When applying the topcoat by roller, it is necessary to ensure that the overall amount is uniform. There should be no flowing or piling of materials, otherwise the problem of mottling will occur.

-

After the colored paint is applied, the topcoat must be completed within the specified time; otherwise, it will affect the adhesion of the topcoat layer.

-

When applying topcoat containing red pigment, there will be a problem of floating color and mottling. It is recommended to switch to epoxy topcoat for construction.

-

This material has a strong odor. It is recommended to wear protective equipment during construction and avoid continuous construction for a long time.

-

The construction site should have good ventilation. Construction should be stopped when feeling unwell and ventilation and air exchange should be carried out in time.

Technical Statement

To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. For special colors or effect designs, we can manufacture them according to your requirements. Our company can form design schemes of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers.

| Construction Process | ||

| Process Name | Specific Methods & Requirements | Single Coat Consumption (kg/m²) |

| Substrate Treatment | 1. Substrate strength: Not less than C20 | / |

| 2. Substrate flatness: ≤5mm when measured with a 2m ruler | ||

| 3. Substrate dryness: Moisture content of substrate surface < 8% | ||

| 4. Repair hollowing and cracks on the ground in advance | ||

| 5. Fully grind the concrete substrate | ||

| Primer Coat | 1. Use single-component polyurethane paint: Roll evenly with a roller | 0.1-0.15 |

| 2. Use a wool brush for edges, corners and machine corners | ||

| Mid-Coat Mortar Layer | 1. Use OVG-0101/OVG-0102: Mix main paint and curing agent in proportion, stir evenly; add quartz sand in proportion and mix uniformly | 0.3 |

| 2. Scrape overall with a trowel; adjust the number of coats as needed | ||

| 3. After curing, grind and remove dust | ||

| Putty Layer | 1. Use OVG-0101/OVG-0102: Mix main paint and curing agent in proportion, stir evenly; add appropriate fillers (quartz powder, talc powder) in proportion and mix uniformly | 0.1 |

| 2. Scrape evenly with a trowel; focus on filling defects like pinholes and air holes; adjust coats as needed | ||

| 3. After curing, fully grind and remove dust | ||

| Topcoat Layer | 1. Use OVG-0101/OVG-0102: Mix main paint and curing agent in proportion, stir evenly | 0.15 |

| 2. Dip the roller into the topcoat and roll evenly; require uniform coating with no missed areas | ||

| Finish Coat | Use OVG-0101 (high-gloss): Stir evenly, then dip and roll uniformly | 0.1-0.15 |

Construction section

Construction conditions

-

Air temperature: 0℃ - 35℃

-

Relative humidity: 20%-80%

-

Moisture content of the base material surface: < 8%

-

The construction site should have good ventilation

-

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating

-

For specific details, please refer to the construction plan.

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English