Products

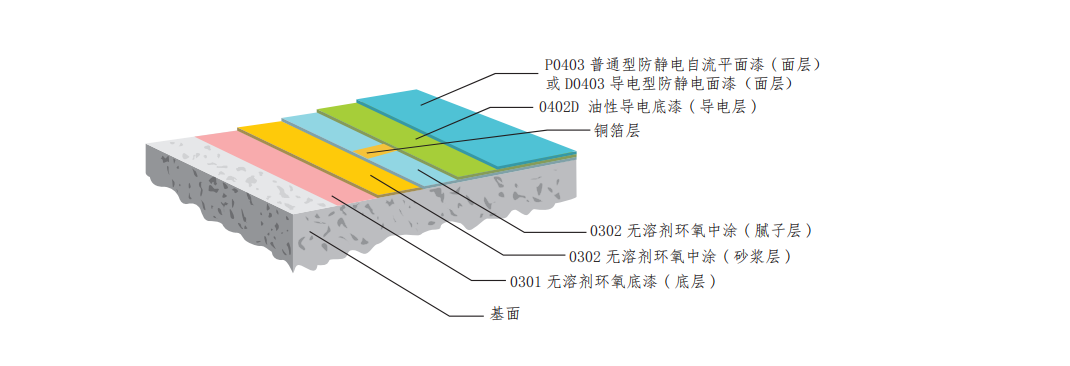

Solvent-free anti-static system

Product Details

Product features

Stable electrostatic conductivity;

The surface is smooth and clean, making it easy to clean.

High mechanical strength, good wear resistance and long service life;

There is no leakage of conductive particles, and it is suitable for dust-proof clean areas.

It can meet different conductive performance requirements such as electrostatic dissipation and electrostatic conduction

Scope of application

It is suitable for the internal concrete surfaces of buildings that require anti-static measures

For industrial floors with relatively heavy loads, such as those for machinery, military industry,

Production workshops and warehouses in industries such as electronics, computers, medicine, and light textiles

| Technical Indicators | |||

| Performance | Technical Indicator | Test Result | |

| Drying Time | Surface dry, h: | ≤ 8 | Compliant |

| Actual dry, h: | ≤ 48 | Compliant | |

| Hardness | Surface dry, h | to be determined | 83 |

| Abrasion Resistance | Shore Hardness | ≤ 0.030 | 0.022 |

| Impact Resistance | 750g/500r | 1000g steel ball, 100cm height, no coating cracks or peeling | Compliant |

| Surface Resistance | Ω | 5×10⁴—1×10⁹ | Compliant |

| Volume Resistance | Ω | 1×10⁴—1×10⁹ | Compliant |

| Matching Instructions | |||||

| Coating Layer | Material Model | Packaging Specification | Mixing Ratio | Single-pass Consumption (kg/㎡) | Single-pass Thickness (mm) |

| Primer Coat | WEDO-0301 Solvent-free Epoxy Primer | 20KG/10KG | 2:01 | 0.15 | 0.15 |

| Mortar Layer | WEDO-0302 Solvent-free Epoxy Intermediate Coat | 25KG/5KG | 5:01 | 0.3-0.5 | 0.5 |

| Putty Layer | WEDO-0302 Solvent-free Epoxy Intermediate Coat | 25KG/5KG | 5:01 | 0.1 | 0.1 |

| (Copper Foil First) | WEDO-0402D Oil-based Conductive Primer | 16KG/8KG | 2:01 | 0.15 | 0.12 |

| Conductive Layer Batch Scraping | |||||

| Topcoat 1 | P0403 General Anti-static Self-leveling Topcoat | 20KG/4KG | 5:01 | 0.8-0.9 | 0.7 |

| Topcoat 2 (Putty Layer 2) | D0403 Conductive Anti-static Topcoat | 20KG/5KG | 4:01 | 0.1 | 0.1 |

| Topcoat 2 | D0403 Conductive Anti-static Topcoat | 20KG/5KG | 4:01 | 0.35 | 0.3 |

| Construction Process | ||

| Process Name | Specific Methods & Requirements | Single-pass Consumption (kg/m²) |

| Base Layer Treatment | 1. Base strength: ≥ C20 | / |

| 2. Base flatness: ≤ 5mm (measured with 2m straightedge) | ||

| 3. Base dryness: Surface moisture content < 8% | ||

| 4. Repair cracks/holes in advance | ||

| 5. Full grinding of concrete base material | ||

| Epoxy Layer (Primer) | 1. Use WEDO-0301: Mix main paint and curing agent in proportion, stir evenly | 0.15 |

| 2. Roll coat evenly | ||

| 3. Brush edges/corners with a brush | ||

| Epoxy Layer (Mortar) | 1. Use WEDO-0302: Mix main paint and curing agent, add quartz sand (80-120 mesh) at 1:0.2-1, stir evenly | 0.3-0.5 |

| 2. Scrape with a trowel (adjust layers as needed) | ||

| 3. Grind after curing to remove dust | ||

| Putty Layer | 1. Use WEDO-0302: Mix main paint and curing agent, add filler (quartz powder/talc) at 1:0.1-0.5, stir evenly | 0.1 |

| 2. Scrape evenly to fill defects (adjust layers as needed) | ||

| Copper Foil Laying | 1. Lay 2-3m × 2-3m copper foil in "well" pattern, press tightly to the ground | / |

| Conductive Layer Scraping | 1. Use WEDO-0402D: Mix main paint and curing agent, stir evenly | 0.15 |

| 2. Scrape evenly to fill defects (adjust layers as needed) | ||

| 3. Test resistance after drying: < 2×10⁴Ω | ||

| Topcoat 1 | Static-dissipative floor: Use WEDO-P0403 static-dissipative topcoat | 0.8-0.9 |

| 1. Roll coat evenly, defoam with a roller | ||

| 2. Note: Putty layer increases resistance (not recommended for anti-static products; apply directly on conductive layer) | ||

| Topcoat 2 | Anti-static floor: Use WEDO-D0403 conductive anti-static topcoat | 0.35 |

| 1. Mix main paint and curing agent, stir evenly | ||

| 2. Roll coat evenly, no missed areas | ||

Notes

The application environment for topcoat: Temperature 5-30℃, relative humidity of air less than 80%. Excessive humidity may affect the strength and conductivity of the conductive layer, causing problems such as mottling and color floating of the topcoat.

Before the conductive layer is applied, it must be repaired and leveled with epoxy materials to completely seal the base surface.

The copper foil must be firmly adhered without lifting. After all the copper foils are connected, the conduction performance needs to be tested to check for any blind spots.

The conductive layer should be applied in one coat. When applying, ensure that the surface is smooth and flat without particles. After the application is completed, the resistance value should be less than 2×104 Ω.

Electrostatic dissipation type topcoat can be applied with topcoat putty, while conductive type topcoat cannot be applied with topcoat putty layer.

When troweling anti-static topcoat, avoid rapid lifting and dragging of the trowel. The formed bubble strings should be punctured with the trowel. After troweling, they must be treated with a defoaming roller.

For troweling construction, the amount of topcoat should be uniform. There should be no local accumulation or flow of materials, otherwise it will cause the conductive filler to float unevenly.

If the anti-static topcoat layer is reworked, the conductive layer must be reapplied; otherwise, the resistance value will not meet the requirements.

There are certain color differences among different batches of materials. When constructing in the same area, the same batch of materials should be used. When placing multiple orders for the same project, it must be noted that the color will be adjusted according to the sample

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

Construction section

Construction conditions

Air temperature: 5℃ -30℃

Relative humidity < 80%

The moisture content of the substrate surface is less than 8%

The construction site should have good ventilation

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating

Oily floors must be thoroughly cleaned up; otherwise, it may affect the even application of the coating.

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English