Products

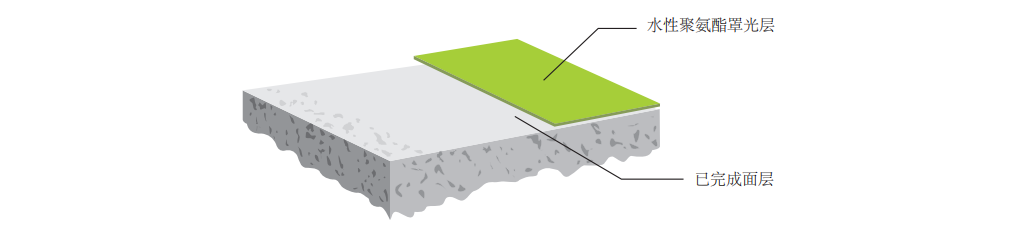

Waterborne polyurethane system

Product Details

Product features

Hydration system, almost odorless;

The coating has a smooth and flat appearance with good decorative properties.

The gloss of high-gloss polyurethane after lamination can reach 70-90 (high gloss)

For top use: 50-70 (for matte top use)

The gloss of matte polyurethane after lamination is ≤ 30.

This product has strong adhesion to various substrates and is not prone to peeling or falling off. It is not prone to yellowing, can enhance surface wear resistance and has a long service life. Anti-mold and antibacterial, it can be used in the pharmaceutical, food and other industries.

Scope of application

It is particularly suitable for floors that need to be kept highly clean and

In places where the construction odor is required to be low, such as hospitals, food factories,

Supermarkets, dairy factories, light industrial plants, warehouses, exhibition halls, schools, etc.

| Technical Indicators | |||

| Performance | Technical Indicator (GB/T22374-2018) | Test Result | |

| Drying Time | Surface dry, h | ≤8 | 3 |

| Actual dry, h | ≤48 | 24 | |

| Hardness | Pencil hardness (scratch) | To be determined | 3H |

| Abrasion Resistance | 750g/500r | ≤0.050 | 0 |

| Slip Resistance | Dry friction coefficient | ≥0.50 | 1 |

| Water Resistance | 168h | No blistering, no peeling, slight discoloration allowed | Compliant |

| Chemical Resistance | Oil resistance (120# solvent gasoline, 72h) | No blistering, no peeling, slight discoloration allowed | Compliant |

| Alkali resistance (20%NaOH, 72h | No blistering, no peeling, slight discoloration allowed | Compliant | |

| Acid resistance (10%H₂SO₄, 48h) | No blistering, no peeling, slight discoloration allowed | Compliant | |

| Matching Instructions | |||||

| Coating Layer | Material Model | Packaging Specification | Mixing Ratio | Single-pass Consumption (kg/㎡) | Single-pass Thickness (mm) |

| Topcoat Layer 1 | WEDO-0704 Waterborne Polyurethane Transparent High-Gloss Topcoat | 16KG/8KG/4KG | 4:02:01 | 0.1 | 0.06 |

| Topcoat Layer 2 | WEDO-0704S Waterborne Polyurethane Transparent Matte Topcoat | 16KG/4KG/4KG | 4:01:01 | 0.1 | 0.06 |

Notes

Strictly control the construction temperature between 10℃ and 30℃, and the relative humidity between 20% and 80%. Construction is prohibited when the ground is damp.

The polyurethane varnish can only be applied after the coating is completely dry; otherwise, there will be problems such as shrinkage and inability to apply.

After the topcoat layer dries, it should be promptly varnished. If left for too long, the surface is prone to contamination, and after varnishing, particles or even delamination may occur.

Water-based polyurethane can only be topcoat on the epoxy material or other materials recommended by our company. When topcoat on other external surface layers, there may be problems such as oil shrinkage and unresolved bubbles. If it is directly applied on inorganic floors, there is a risk of delamination and peeling.

When in use, first mix components A and C, stir evenly, and then add Component B. The addition sequence must be strictly followed.

When applying waterborne polyurethane by roller coating for topcoat, a short and medium-bristled roller should be used, and the coating should be applied in two coats horizontally and vertically to ensure even coating without any omissions.

Waterborne polyurethane dries relatively quickly. During construction, pay attention to controlling the joint marks, which should not exceed 10 minutes.

Water-based polyurethane matte products are less dirt-resistant compared to glossy ones. Once they get dirty, they must be cleaned promptly. Factories and garages should be cautious when choosing them.

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

| Construction Process | ||

| Process Name | Specific Methods & Requirements | Single-pass Consumption (kg/㎡) |

| Topcoat Layer | After the topcoat layer is completely dry, different topcoat clear coats can be selected to change the surface gloss while improving the surface scratch resistance. | 0.1 |

Construction section

Construction conditions

Air temperature: 10℃ - 30℃

Relative humidity: 20% - 80%

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating.

Oily floors must be thoroughly cleaned up; otherwise, it may affect the even application of the coating.

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English