Products

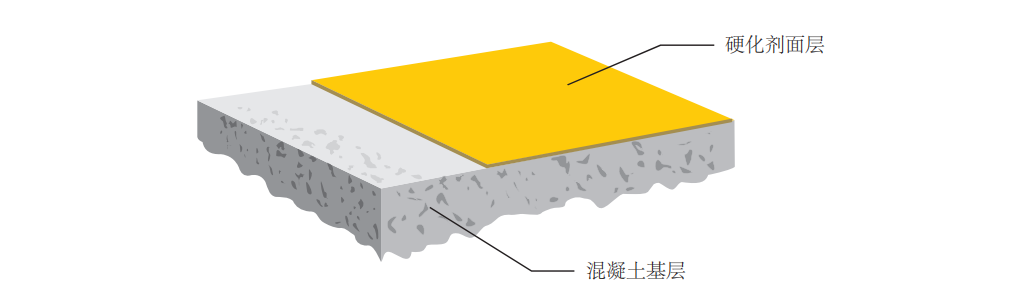

Metal and non-metal wear-resistant hardener floor system

Product Details

Product features

-

Metal aggregates can be classified as: copper ore sand, iron ore sand, silicon-titanium alloy, quartz sand, mica stone, etc.

Highly wear-resistant and with excellent impact resistance;

-

Cost-saving, long service life, and no maintenance required;

-

Anti-slip and dust-proof;

-

It can enhance the resistance to oil and grease.

-

Optional colors: gray (cement color), green, red, etc

Scope of application

It is applicable to light and heavy industrial plants, parking lots, warehouses, supermarkets, exhibition halls, squares, auto repair shops, food processing plants, cold storage facilities, water treatment centers and other places where the ground is required to be clean, stain-resistant and wear-resistant.

| Technical Indicators | |||

| Item | Index | ||

| Non-Metal Orthopedics | Metal Orthopedics | ||

| Abrasion Resistance (g/cm²) | ≤ 0.03 | ≤ 0.03015 | |

| Compressive Strength (Mpa) | 3 days | 48.3Mpa | 49Mpa |

| 7 days | 66.7Mpa | 67.2Mpa | |

| 21 days | 77.6Mpa | 77.6Mpa | |

| Flexural Strength (Mpa) | > 9 | > 12 | |

| Tensile Strength (Mpa) | 3.3 | 3.9 | |

| Rebound Value | 46 | 46 | |

| Mineral Scale | 10 | 10 | |

| Mohs Hardness (28 days) | 7 | 8 | |

| Anti-slip Property | Same as ordinary cement floor | Same as ordinary cement floor | |

Packaging ratio

-

Product Names: WEDO-0901, WEDO-0902

-

Packaging specification: 25kg per package

-

Warranty period: Store in a cool (5℃ -30℃), dry place and protected from moisture. Under the original sealed condition, it is 12 months.

Notes

-

The construction site should have good ventilation and all equipment should be explosion-proof.

-

Construction tools can be washed with clean water.

-

Construction workers should have good protective measures. If this product gets on the skin, eyes, etc., please wash it off immediately with clean water.

-

Construction conditions and base material preparation should be strictly carried out in accordance with the product manual.

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

| Construction Process | ||

| Process Name | Specific Methods and Requirements | Single Coat Usage (kg/㎡) |

| Concrete Leveling | 1. After concrete is screeded and reaches initial set, use a troweling machine with a disc to evenly break the laitance layer on the concrete surface, then level the concrete with a long straightedge. | / |

| First Aggregate Spreading | 2. Spread the wear-resistant hardener material: the first spread should account for 2/3 of the total amount. When the hardener absorbs moisture and turns uniformly darker, use the troweling machine for rough leveling. | 4 |

| Second Aggregate Spreading | 3. The second spread accounts for 1/3 of the total amount. Spread evenly over the large area; increase the amount in laitance or discolored areas, and focus on repairing defective parts. Use the troweling machine for fine leveling. | 2 |

| Leveling and Finishing | 4. When the concrete is hard enough to avoid damage, use the troweling machine for leveling and finishing. | / |

| Floor Curing | 5. Cure the floor: After polishing, cure it by sprinkling water or spraying a special floor curing agent. | / |

Construction section

Construction conditions

-

Air temperature: 5℃ - 30℃

-

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating.

-

For specific details, please refer to the construction plan.

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English