Products

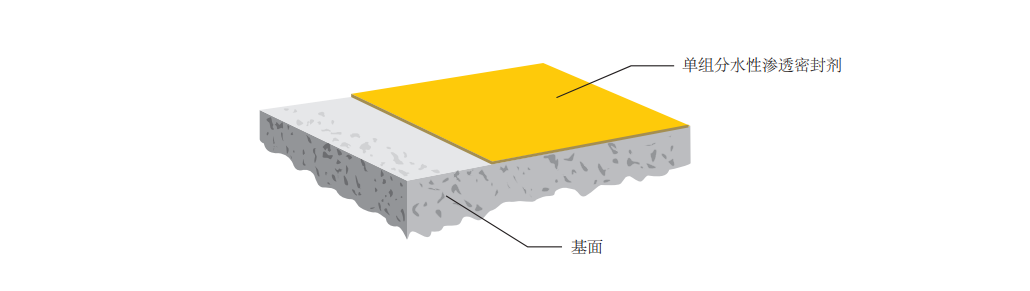

One-component water-based penetrating sealant

Product Details

Product features

Shrink the pores of concrete and effectively prevent external pollutants from entering the concrete.

Enhance the surface hardness, wear resistance and compressive strength of both new and old concrete floors;

It can prevent the infiltration of carbon dioxide and moisture, inhibit the neutralization of concrete and prevent the corrosion of steel bars

It can prevent concrete from peeling and cracking and has excellent dust-proof performance.

The treated floor will have a marble-like luster. The longer it is used, the better the luster and the more beautiful the appearance. It is convenient for cleaning and sweeping, and saves maintenance and management costs.

Scope of application

It is particularly suitable for industrial plants and underground garages in industries such as electrical appliances, electronics, machinery, food, medicine, chemicals, tobacco, feed, textiles, clothing, furniture, plastics, and cultural and sports goods.

| Technical Indicators | |||

| No. | Test Item | Technical Index (JC/T 2158-2012) | Test Result |

| 1 | Solid Content (%) | Specified to ±2% | Compliant |

| 2 | pH Value | ≥ 11.0 | 12 |

| 3 | 24h Surface Water Absorption (MM) | ≤ 5 | 1 |

| 4 | 24h Surface Water Absorption Reduction Rate (%) | ≥ 80 | 90 |

| 5 | Abrasion Resistance Ratio (%) | ≥ 140 | 185 |

| 6 | VOC (g/L) | ≤ 30 | Not Detected |

Packaging ratio

Packaging specification: WEDO-0903, 20kg per set, ratio: Single-component use

Notes

The penetrating sealant can only be applied to the concrete floor when it reaches the curing period.

For old floors, surface coatings (such as wax layers, curing agents, resin-based paints, etc.) and oil stains should be removed first. For floors with severe oil stains, appropriate treatment is required before the application of penetrating sealant.

After the application of the penetrating sealant, it needs to be dragged in time. Water can be sprinkled to dilute it and help with penetration.

Excess penetrating sealant should be cleaned up in time to avoid causing the ground to turn white.

It can be ground and polished to a certain mesh size according to the required effect.

Construction workers should have good protective measures. If this product comes into contact with the skin, eyes, etc., it should be washed immediately with clean water.

Construction conditions and base material preparation should be strictly carried out in accordance with the product manual.

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

| Construction Process | ||

| Process Name | Specific Methods and Requirements | Single Coat Usage (kg/m²) |

| Substrate Grinding | 1. Clear debris and dampen the floor | / |

| 2. Grind the floor with 50# metal grinding discs to remove laitance and debris | ||

| 3. Grind sequentially with 50# and 150# resin discs to eliminate rough grinding marks, fully open pores, and help the sealer penetrate into the concrete | ||

| 4. Clean the floor, dry completely, and prepare for sealer application | ||

| Applying Penetrating Sealer | 1. Spray WEDO-0903 penetrating sealer evenly on the floor surface, keep it moist for 2–4 hours; use a roller to push back and forth to assist absorption | 0.3 |

| 2. When the sealer thickens, spray appropriate water to dilute excess sealer, then roll back and forth for secondary absorption | ||

| 3. When the sealer thickens again, rinse off excess with clean water | ||

| Machine Polishing (Optional) | After the floor is fully hardened, polish it with 300# to 1000# resin discs using a polishing machine; polish to the required grit as needed | / |

Construction section

Construction conditions

Air temperature: 5℃ - 30℃

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English