Products

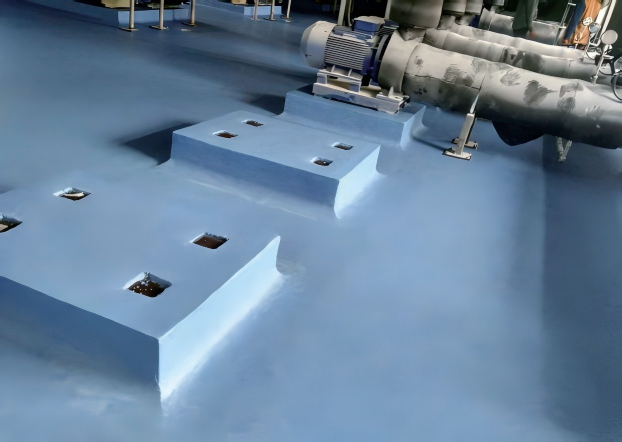

Epoxy resin colored sand system

Product Details

Product features

The surface is smooth and clean, with bright colors and excellent decorative effect.

Good mechanical strength, anti-slip and waterproof;

Wear-resistant, pressure-resistant, impact-resistant, and has good chemical resistance.

It can be made into a smooth or rough surface as required and has an outstanding anti-slip function

Scope of application

It is mainly applicable to floor scenarios that require high strength, high mechanical performance, good appearance and wear resistance, such as large shopping malls, exhibition halls, subways, electronic communication, medical and health care, airports and other places. It can also be used in high-end entertainment venues, business buildings, exhibition centers, large shopping malls, offices and other places with higher requirements.

| Technical Indicators | |||

| Performance Category | Performance Parameter | Technical Index (GB/T22374-2018) | Test Result |

| Drying Time | Surface Dry, h | ≤ 8 | Compliant |

| Actual Dry, h | ≤ 48 | Compliant | |

| Hardness | Shore Hardness | Agreed | 83 |

| Abrasion Resistance | 750g/500r | ≤ 0.030 | 0.023 |

| Impact Resistance | Heavy Load | 1000g steel ball, 100cm height; no coating cracks or peeling | Compliant |

| Anti-slip Property | Dry Friction Coefficient | ≥ 0.50 | 0.61 |

| Water Resistance | 168h | No blistering, no peeling; slight discoloration allowed | Compliant |

| Chemical Resistance | Oil Resistance (120# Solvent Gasoline, 72h) | No blistering, no peeling; slight discoloration allowed | Compliant |

| Alkali Resistance (20% NaOH, 72h) | |||

| Acid Resistance (10% H₂SO₄, 48h) | |||

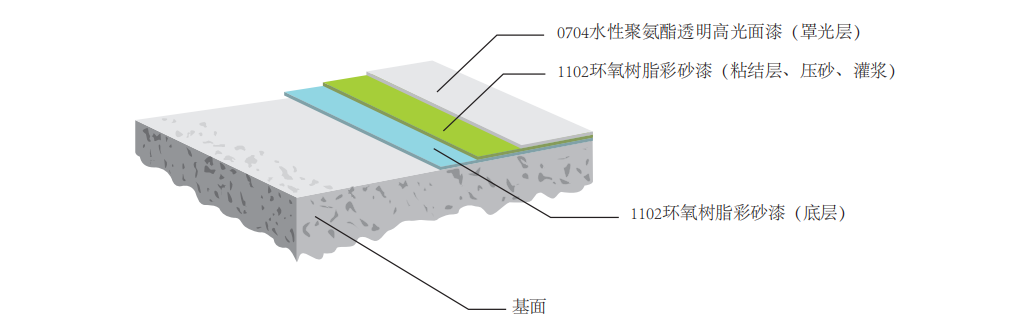

| Matching Instructions | |||||

| Coating Layer | Material Model | Packaging Specification | Mixing Ratio | Single Coat Usage (kg/m²) | Single Coat Thickness (mm) |

| Primer | WEDO-1102 Epoxy Resin Colored Sand Paint | 20KG/8KG | 2.5:1 | 0.3–0.4 | 0.3–0.4 |

| Bonding Layer | WEDO-1102 Epoxy Resin Colored Sand Paint | 20KG/8KG | 2.5:1 | 0.20 | 0.00 |

| Sand Pressing Layer | WEDO-1102 Epoxy Resin Colored Sand Paint | 20KG/8KG | 2.5:1 | 1.0–1.5 | 5–7 |

| Grouting Layer | WEDO-1102 Epoxy Resin Colored Sand Paint | 20KG/8KG | 2.5:1 | 0.5–2 | 0.00 |

| Topcoat 1 | WEDO-0704 Waterborne Polyurethane Clear High-Gloss Varnish | 16KG/8KG/4KG | 4:02:01 | 0.10 | 0.06 |

| Topcoat 2 | WEDO-0704S Waterborne Polyurethane Clear Matte Varnish | 16KG/4KG/4KG | 4:01:01 | 0.10 | 0.06 |

Notes

When spreading colored sand, the surface must be flat and attention should be paid to the uniformity of the colored sand spreading.

During the construction process, a dedicated person must repeatedly check the flatness of the paving surface with a straightedge. Special personnel should be assigned to handle the elevation at the skirting boards and corners to ensure the overall flatness of the ground.

Construction conditions and base material preparation should be strictly carried out in accordance with the product manual.

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

| Construction Process | ||

| Process Name | Specific Methods and Requirements | Single Coat Usage (kg/m²) |

| Substrate Treatment | 1. Substrate strength: Not less than C20 2. Substrate flatness: ≤3mm (measured with a 2m ruler) 3. Substrate dryness: Moisture content of substrate surface < 8% 4. Repair hollowing and cracks on the ground in advance 5. Fully grind the concrete substrate 6. Level the skirting lines and corner areas | / |

| Primer Layer | 1. Use WEDO-1102: Mix base paint and curing agent in proportion until uniform 2. Apply evenly by roller coating or knife coating 3. Ensure no whitening or missing application areas | 0.3–0.4 |

| Sand Pressing Layer (Bonding Layer) | 1. Apply the bonding layer before sand pressing: Use WEDO-1102, apply evenly by roller or knife coating to cover the entire floor 2. Use WEDO-1102: Mix base paint and curing agent in proportion, then add colored sand at the recommended ratio (Paint:Colored sand = 1: 10–16); use a vertical mixer for uniform stirring 3. Spread the mixed colored sand evenly on the bonding layer as required, level with a straightedge to control flatness; press corner areas manually with force 4. Level and press with a troweling machine, and control flatness | 1.0–1.5 |

| Grouting Layer | 1. Use WEDO-1102: Mix base paint and curing agent in proportion until uniform 2. Pour evenly with a knife to ensure overall uniform grouting | 0.5–2 |

| Topcoat Layer | Use WEDO-0704/WEDO-0704S: Mix materials in proportion, fully emulsify, then apply evenly by roller coating; ensure uniform layers with no material accumulation or missing application areas | 0.1 |

Construction section

Construction conditions

Air temperature: 5℃ - 30℃

Relative humidity < 80%

The moisture content of the substrate surface is less than 8%

The construction site should have good ventilation

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating. Oily floors must be thoroughly cleaned up; otherwise, it may affect the even application of the coating.

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English