Products

Cement-based self-leveling system

Product Details

Product features

-

Rapid curing - It can quickly pass pedestrian traffic, thereby accelerating the progress of subsequent work;

-

Simple construction - No need to spend a lot of time and labor on the construction of the cement-based surface leveling layer.

-

It has excellent flow performance, which can greatly enhance the service life and decorative effect of various flooring materials.

-

It has excellent compressive and tensile strength, and outstanding water and alkali resistance

Scope of application

Hospitals, food factories, light industrial plant equipment manufacturing and various light industrial production areas, shopping malls, warehouses, underground garages, exhibition halls, schools, electronic and microelectronics industries, etc

| Technical Indicators | |||

| Item | Technical Index | ||

| Type I (Commercial) | Type II (Industrial Heavy-Load) | ||

| Flowability, H | Initial Flowability, min | ≥ 130 | ≥ 140 |

| 20min Flowability, min | ≥ 130 | ≥ 140 | |

| 28d Compressive Strength, MPa | ≥ 25 | ≥ 35 | |

| 28d Flexural Strength, MPa | ≥ 7 | ≥ 9 | |

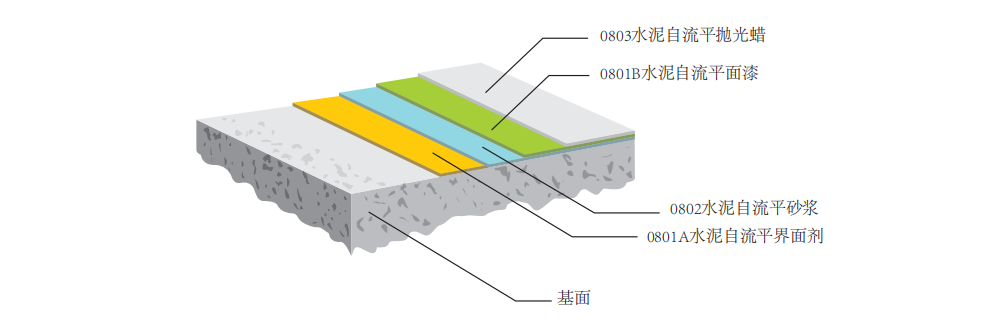

| Matching Instructions | ||||

| Coating Layer | Material Model | Packaging Specification | Single Coat Usage (kg/m²) | Single Coat Thickness (mm) |

| Primer | WEDO-0801A Cement Self-Leveling Interface Agent | 25KG | 0.2 | 0.1–0.15 |

| Mortar Layer | WEDO-0802 Cement Self-Leveling Mortar (High Strength) | 25KG | 1.7 | 1.0–1.5 |

| Topcoat Layer | WEDO-0801B Cement Self-Leveling Topcoat | 20KG | 0.1 | 0.05–0.1 |

| Protective Layer | WEDO-0803 Cement Self-Leveling Polishing Wax | 5KG | 0.1 | 0.05–0.1 |

| Construction Process | ||

| Process Name | Specific Methods and Requirements | Single Coat Usage (kg/m²) |

| Substrate Treatment | The substrate must be clean, dry, and firm (strength > C20) with no structural defects. Grind the entire floor with a grinder, and repair cracked, peeling, or damaged areas. | / |

| Applying Interface Agent | Use WEDO-0801A cement self-leveling interface agent; apply evenly without gaps, and ensure no surface residual fluid. | 0.20 |

| Cement Self-Leveling Construction |

Use WEDO-0802 cement self-leveling mortar: 1. Pre-mix cement first; with an electric mixer running, slowly pour the self-leveling cement into clean water in a suitable container. Stir continuously until a particle-free, uniform fluid mixture forms. Mixing ratio: 25kg self-leveling cement + ~6L water. 2. Pour the mixture evenly into the construction area, and spread it to the required thickness with a toothed trowel. Must be completed within 15 minutes. 3. Before the self-leveling mortar initializes, walk on the surface with special spiked shoes, and roll the floor with a bubble-removing roller to eliminate air trapped during mixing. 4. After 24 hours of construction, various floor materials can be laid or epoxy floors can be applied. |

8.5 (for 5mm thickness) |

| Topcoat Application | Use WEDO-0801B cement self-leveling topcoat to seal the material’s pores; apply evenly with no gaps or accumulation. | 0.10 |

| Protective Layer | After the sealer dries, apply WEDO-0803 cement self-leveling polishing wax evenly. | 0.10 |

Construction section

Notes

-

Construction environment requirements: The ground should be dry, with a temperature not lower than 10℃, and the relative humidity of the ground should be maintained below 90%. There should be no rain or snow, and no overly strong through drafts to avoid premature local drying. If the summer is hot and the temperature is high, it is advisable to choose night construction.

-

Self-leveling land has relatively high requirements for the base layer. The base layer must not have loose concrete, grease, debris, and dust must be sucked clean. The floor drains, trenches, and division joints on the ground should be sealed with sponge strips first. The reserved joints of the original cushion layer should be sealed with the same material as the self-leveling mortar.

-

Before self-leveling construction, it is required that the surface of the interface agent be dry to achieve better connectivity. Attention should be paid to maintaining ventilation during construction. The interface agent is not freeze-resistant. When stored and transported at low temperatures, it should be kept warm.

-

It is best to use clean tap water for construction to avoid affecting the surface appearance quality.

-

Self-leveling floors must be constructed continuously without any breaks in between. The usage time after adding water is 20 to 30 minutes. Beyond this time, the self-leveling mortar will gradually solidify, develop strength and lose fluidity.

-

In cold conditions, stir with warm water (the water temperature should not exceed 35℃).

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

Construction conditions

-

Air temperature: 10℃ - 30℃

-

Relative humidity: ≤ 90%

-

Oily floors must be thoroughly cleaned up; otherwise, it may affect the even application of the coating

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English