Products

Polyurethane elastic sports floor system

Product Details

Product features

Acid-resistant, alkali-resistant, corrosion-resistant, wear-resistant, aging-resistant, comfortable and durable, suitable for all-weather use.

High-temperature resistant, low-temperature resistant, UV-resistant, and environmentally friendly.

The bottom of the watch is integrally cast, and the granular surface will not fall off even after long-term use, maintaining a good competition environment.

A stable friction layer is formed on the surface, allowing athletes' running shoes to firmly grip the ground and promote improvement in competition performance.

The softness and hardness of the sports venue can be adjusted during the laying process according to the different requirements of various competitions and training events for the sports venue.

The novel and colorful track design changes the monotonous image of the competition venue

Scope of application

It is suitable for paving in special environments such as track and field competition tracks, leisure squares, senior apartments, youth activity centers, kindergartens, and family courtyards.

| Technical Indicators | ||

| Coating Performance | Technical Index | Test Result |

| Tensile Strength | ≥0.4MPa | 1.09 MPa |

| Elongation at Break | ≥40% | 71.00% |

| Shore Hardness | 45–60 degrees | 56 degrees |

| Compression Recovery Rate | ≥95% | 99.00% |

| Rebound Value | ≥20% | 34.00% |

| Flame Retardancy | Class 1 | Class 1 |

| Anti-slip Rate | 47BPN (20°C) | 47BPN (20°C) |

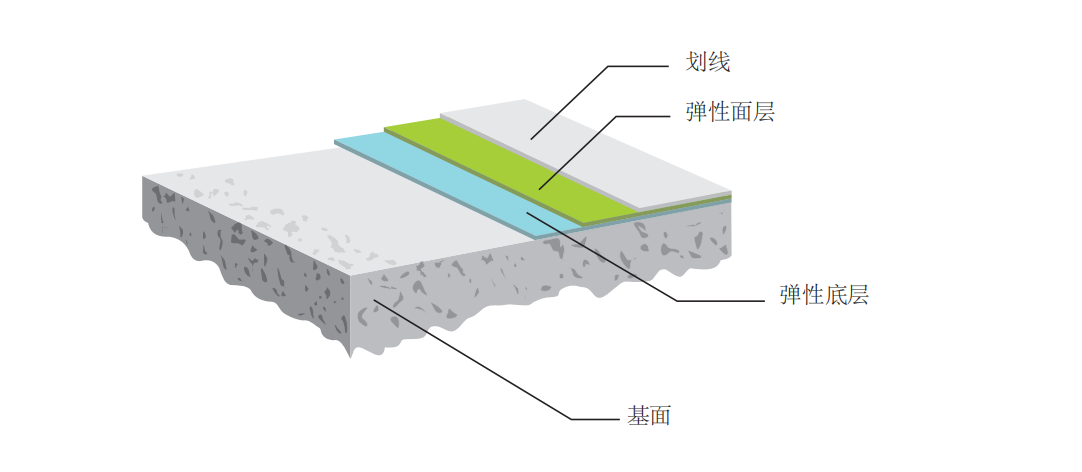

| Construction Process | |

| Process Name | Specific Methods and Requirements |

| Substrate Treatment | 1. Check the substrate flatness: Measure with a 3m straightedge; the error should be within 3mm, and the entire area should be flat. Ensure the site drainage slope meets requirements. |

| Base Adhesive Paving | For the base layer: Mix 3–4mm particle-sized high-elastic black rubber granules with high-strength single-component glue. Pour the mixture into a paver and lay it to a thickness of 10mm. Cure for 24 hours. |

| Surface Adhesive Paving | For the surface layer: Mix breathable surface layer special glue with equal amounts of 1–2mm particle-sized EPDM granules and an appropriate amount of thinner. Pour the mixture into a spraying machine, tilt the spray gun to 60° for unidirectional spraying. Cure for 24 hours, then spray again in the opposite direction. |

| Line Marking | Accurately measure the position of process lines according to current athletics field facility standards, and mark the lines with professional polyurethane white paint. |

Construction section

Notes

Measure the position of the construction line according to the process requirements and place the construction line properly.

When laying, start from one side of the site and apply the adhesive at one time according to the width of the site.

When applying the glue, the speed should be uniform. Timely fill in the glue or smooth out the exposed base, depressions and protrusions.

After the adhesive is formed, conduct a timely inspection of the entire site to ensure the thickness of the surface adhesive laid.

Before laying the adhesive during construction, it is necessary to first understand the weather conditions and be prepared for sudden showers. The time for applying adhesive should avoid the morning when the humidity in the atmosphere and on the ground is relatively high.

Prevent local bubbling and peeling after the rubber surface is laid

Technical Statement

Our company can design construction plans of different specifications (thickness, effect, etc.) through flexible matching and combination of various products to meet the personalized requirements of all kinds of customers. To ensure that your project can select the appropriate floor system, please consult our professional technical advisors. However, when using our company's products, please strictly follow the construction process, dosage requirements and precautions of the product. Otherwise, our company will not bear any responsibility for the quality of the project or any losses.

Construction conditions

Air temperature: 5℃ - 30℃

Relative humidity: 20%-85%

Moisture content of the base material surface: ≤ 8%

The construction site should have good ventilation

Dew point temperature: The substrate and the substrate of the uncured coating must be at least 3℃ higher than the dew point temperature to reduce the risk of condensation or mottling of the ground coating. The ground with oil stains must be thoroughly cleaned; otherwise, it may affect the uniform application of the coating

Indonesian

Indonesian  Malay

Malay  Vietnamese

Vietnamese  Slovenian

Slovenian  Slovak

Slovak  Latvian

Latvian  Bosnian

Bosnian  Icelandic

Icelandic  Ukrainian

Ukrainian  Georgian

Georgian  Serbian

Serbian  Croatian

Croatian  Belarusian

Belarusian  Romanian

Romanian  Estonian

Estonian  Hungarian

Hungarian  Czech

Czech  Catalan

Catalan  Norwegian

Norwegian  Lithuanian

Lithuanian  Albanian

Albanian  Hindi

Hindi  Italian

Italian  Finnish

Finnish  Arabic

Arabic  Danish

Danish  Bulgarian

Bulgarian  Thai

Thai  Polish

Polish  Swedish

Swedish  Greek

Greek  Portuguese

Portuguese  Dutch

Dutch  Turkish

Turkish  Russian

Russian  Deutsch

Deutsch  French

French  Korean

Korean  Japanese

Japanese  English

English